(Written with support from Dr. Gunter Horn.)

In 2001, the Milwaukee Brewers erected a statue to three iron workers who were killed during construction of their new baseball stadium, Miller Park. Jefferey Wischer, William DeGrave and Jerome Starr lost their lives on July 14, 1999 at approximately 5:12 p.m. when a crane named “Big Blue” collapsed while lifting a section of the stadium’s retractable roof. Through an investigation of this incident and the causes related to it, we rediscover that safety is the responsibility of everybody.

The very first retractable roof ballpark was the Civic Arena in Pittsburgh, Pennsylvania built in 1958. By the 1990s retractable roof stadiums became the rage. Miller Park was one of five retractable roof ballparks that were completed between 1998 and 2001. Big Blue was specially leased for the construction of Miller Park, home of the Brewers.

For Miller Park, a special crane was required to lift the roof sections. Big Blue was a monster—a 567-foot LTL-1500 Transi-Lift heavy lift crawler crane that could lift more than 450 tons. It had a somewhat unique configuration, consisting of two separate crawlers 100 feet apart and connected by a space frame structure called a stinger.

The front tub rotated on the front crawler using a king pin as a pivot. The king pin was 12 inches in diameter, 11 feet long—a solid shaft made of 4340 steel with a yield strength of 103,000 psi.

Assembling the retractable roof atop the ballpark would take 30 planned lifts. The first nine lifts were completed without incident. The tenth lift was set to hoist 400 tons when the collapse event occurred. Midway through, Big Blue fell onto another crane with a man-basket. The second crane collapsed, resulting in the fatalities and injuries. The decedents fell 200 feet to the ground.

What sets the Big Blue collapse apart is the existence of a video which depicts this tragic collapse. The video captures the booming sound of the kingpin failing and the horrified reactions from those witnessing the event. The video was filmed by a Division of Occupational Safety and Health (OSHA) inspector. The full video of the collapse can be viewed here, or you can watch a shortened version below:

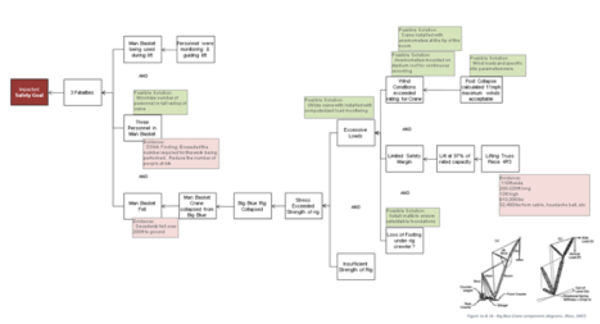

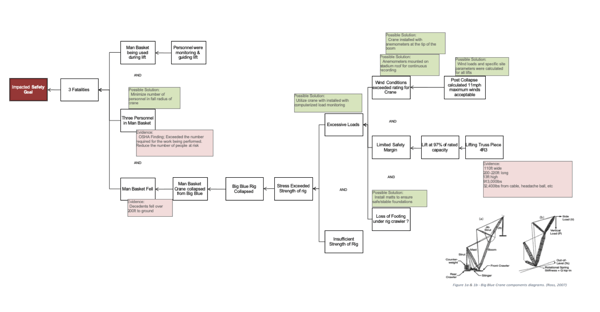

The Cause Map™ diagram, a visual format for performing a root cause analysis, allows us to intuitively lay out the report information to quickly show the cause-and-effect relationships that led to this issue. The first step in the Cause Mapping® method is to fill in an outline with basic background information and a list of how the incident impacts the goals of the organization. An outline for this incident could look like this:

There are additional impacts that could be added to the outline, but it was kept relatively simple for this example. Once the outline is completed, the next step is to analyze the incident by building the Cause Map diagram. Start with one of the impacted goals and ask Why questions to begin. A 5-Why Cause Map diagram for this incident could look like this:

Starting with the five Why questions is a good place to start, but clearly, more detail is needed to understand this incident. The Cause Map diagram is expanded by continuing to ask Why questions.

Cause Map diagrams rarely lay out in a straight line. A branch occurs when there are multiple answers to a Why question (meaning there are two or more causes that contribute to an effect). For example, the wind conditions far exceeded what was later determined to be acceptable. (Click here to download the Cause Map PDF file.)

A System of Causes

The Cause Mapping method does not identify a single cause for an incident, but a system of causes that lead to the issue at hand. Over the past three months, I’ve done some investigation into the Big Blue collapse and the system of causes has become clearer. Additional relevant information included:

- The video on YouTube was taken by an OSHA inspector. The OSHA inspector was there because of several previous incidents involving serious injuries. Some of the previous incidents at the site prior to the crane collapse were:

- An employee fell about 80 feet and survived by hitting an occupied scaffold. The employee that fell was back at work in a few weeks while the person on the scaffold was put on disability.

- A grinding wheel bounced off the surface being smoothed and hit a user in the leg.

- A 25-ton roof section shifted in a sling and broke a man's leg.

- An explosion occurred while a heater was being lit, burning two employees.

- The prime contractor supervisor had fired one of the lift company supervisors for slowing things down with respect to soil/gravel base additions for the crawler.

- The prime contractor supervisor was characterized at the trial by witnesses as "sloppy" in his approach to safety and "authoritarian" in his response to subordinates who expressed concerns about safety procedures.

- There were unclear authority and procedures for calculating the wind loads and measuring wind speed.

- A computer was disconnected immediately after the collapse. That computer had all the measured and recorded wind data. All of the data was lost.

- The crane operator and several iron workers had verbally questioned concerns about wind conditions on the day of the event.

- The tenth lift was the collapse event. There was a 17-day delay between the first and second lifts.

- There were contractor penalty clauses for being late. The incentives were driving an attempt to open the stadium prior to the 2000 baseball season.

- Over $100,000,000 in fines, penalties and lawsuits resulted from the tragedy.

Conclusion

The rig was operating at 97 percent of its rated capacity. The prime contractor faced penalties for delays, which may have contributed to the motivation for firing the lift company supervisor. The responsible person/group for calculating wind loads was not clearly identified, which lead to allowing the operation to move forward despite the fact that the wind conditions exceeded the rating for the crane. All of the causes had to happen for this tragedy to occur. Because multiple causes have been identified, there are multiple potential solutions to choose from to prevent an event like this from occurring again. This Cause Map brings up some heartrending points about how safety is the responsibility of everyone.