A common failure mode in many investigations occurs when something breaks. In this post, I am going to provide an introduction to one of many fundamental cause-and-effect relationships that can help with your analysis and, ultimately, provide additional opportunities to prevent recurrence.

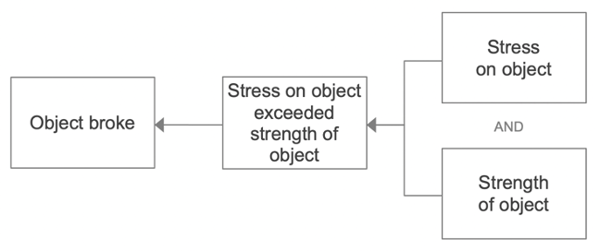

When facilitating an investigation, we know that if something does break, then we have evidence that stresses on the object exceeded the strength of the object. This is represented visually within the Cause Mapping® approach as shown below. This relationship also applies any time something buckles, cracks, fractures, strains or sprains.

Represented visually, you can see that both stress AND strength are causes that are REQUIRED to produce the break. If both causes are required, then which one must you control to reduce the risk of the break? The most common answer we hear in our workshops is, “Well, if they are both causes, then you must control both of them.” That answer, however, is incorrect. Since BOTH are required to produce the break, then controlling either cause will reduce the risk of the break. This simple takeaway is significant because it implies you may have multiple solution options.

You can keep the strength as is and implement a solution to reduce the stress, do nothing about the stress and focus your solution around increasing the strength, or implement solutions for both by increasing the strength and addressing the stress. Ultimately, your ability to avoid the break will be determined by the effectiveness of your solutions. However, if you implement solutions for both causes, you can significantly reduce the risk.

It is important to note that the causes are not implying there is anything wrong with the strength of the object. A common misconception with analyzing a problem is that any causes revealed must be bad or wrong. However, even though the strength of the object may be exactly as it was designed, we can still implement a solution to increase its strength in an effort to reduce the risk of recurrence going forward. At the end of the day, it should be the best solutions that dictate what we choose to implement for the organization.

The causal relationship for a break applies in every instance you have a break, crack, buckle, tear, etc. It represents one of several fundamental relationships you can apply during an investigation. While the causes in this instance are specific to a break, the leverage you reveal for additional risk reduction with the parallel relationship is one that applies in other fundamental relationships as well. For example, think about what causes are fundamentally (always) required for a leak, a collision, a fire, a fall or even a deviation such as a delay. Applying the lessons presented here can help you reveal more opportunities to reduce risk and drive reliability.

If you’re interested in learning more about the application of these fundamental relationships and our Cause Mapping approach, I invite you to attend one of our upcoming Cause Mapping workshops or other training opportunities.