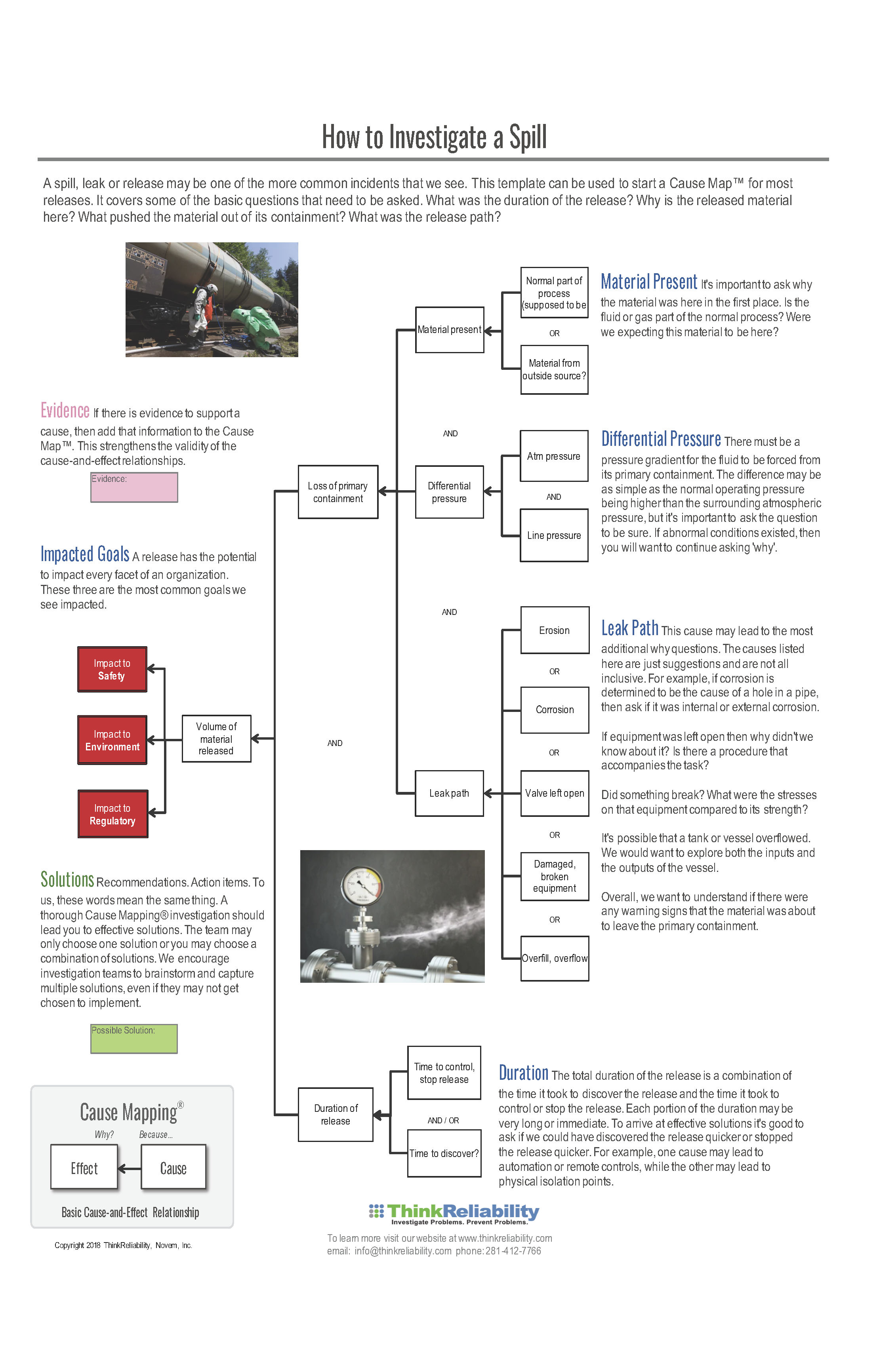

A loss of primary containment, also known as a spill or a release, is a common incident that occurs at many organizations. The released material may be a solid, liquid or gas. The commonality is that the material or product escaped its vessel, pipeline or container that it was supposed to be in. This Cause Map™ example contains the basic building blocks to complete a root cause analysis investigation. There are four high-level questions to ask anytime something is spilled or released. We will cover each one of these questions and provide guidance for each one.

1. Duration of release

Anytime a spill occurs, it is because there was a loss of primary containment for a duration of time. The total volume released depends on the duration. The greater the duration, the greater potential for the total release volume.

The duration of a release can further be broken down into two parts: 1) time to discover the release and 2) the time it took to control or stop the release. Each of these components could be either very short, a matter of seconds, or, very long—lasting days or even weeks. Depending on which component of duration contributed the most to the release volume, you may end up with different solutions.

2. Material Present

Why is the material here? Most of the time this is an easy answer. It is supposed to be in the system. It is part of the normal process. However, sometimes the spilled material is from an outside source. Maybe rain infiltrated the system and caused something to go wrong. Maybe a different product was mistakenly introduced to the system and is causing problems.

3. Differential Pressure

This question may not apply to every release, but it is important to ask if there was a change in pressure inside the system. It is not uncommon for an overpressure event to contribute to a release. Additionally, if the pressure drops or a vacuum is created, this may cause damage to equipment that, then, provides a leak path later. It’s important to establish if normal pressure conditions were present at the time of the release.

4. Leak Path

This is the area that most people think of when they begin an RCA investigation into a spill. Where is the hole or opening in equipment that allowed the material to escape? The causes listed on the template are some of the most common we see. This list is not all inclusive. It is meant to give you ideas to continue asking why questions. Erosion and corrosion are common causes we see when dealing with pipelines. Sometimes equipment is inadvertently left open. Other times, equipment was damaged or broken from a different event.

An overflow or overfill event can also be considered a loss of primary containment. If this is the case, then you can ask about the inputs and outputs to better understand where the imbalance of material occurred. Did the inputs remain “normal” and the outputs slowed down or stopped? Did the inputs increase while the outputs remained “normal”?

This Cause Map™ is meant to be used as a starter template when you need to conduct an RCA on a spill or release. Each one of these causes has the potential to lead to more why questions. Keep asking and answering the why questions until you have revealed enough causes to explain the incident thoroughly. Then, you can target specific causes that are within your control to develop solutions that will reduce the likelihood of a similar incident happening again.