Problem-solving and problem prevention

Think cause-and-effect basics

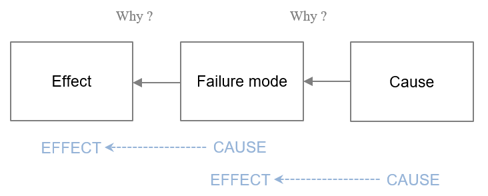

Cause Mapping® root cause analysis is based on cause-and-effect. By working backward, a Cause Map™ diagram reveals the cascade of events that produced a problem. Basic and complex problems are both explained with simple cause-and-effect relationships. A Cause Map diagram provides a visual layout of how all the causes fit together. It’s a platform for identifying different solution options. Cause-and-effect is the basis of both root cause analysis and FMEA.

Failure modes, effects and causes

A conventional FMEA is built into a table so that numbers can be attributed for severity, consequence

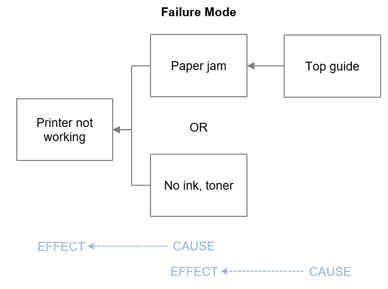

Printer jam example

The relationship between failure modes, effects and causes

There are other ways the printer can lose function. It can be out of paper, lose power or there can be an issue with the network connection. And there are different failure modes (causes) for each of those. Capturing this type of detail is essential for organizations to have a complete understanding of their problems – to prevent them. Many industries take full advantage of this tool. Many do not.

The manufacturer of an

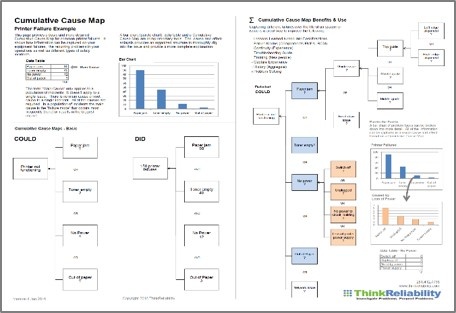

Visual FMEA - A Cumulative Cause Map™

An FMEA table may be 10 failure modes, 1,000 or 10,000. An FMEA table may fit on one page or fill a 150-page binder. Regardless of size, all the information from an FMEA can also be captured on one visual Cause Map diagram. We call it a cumulative Cause Map diagram because it’s a collection of all the different failure modes. A cumulative Cause Map doesn’t replace the FMEA, it complements it. A cumulative Cause Map diagram is ideal for recurring safety incidents, equipment failures or operational problems. Aggregate information is captured in one place. It can

Download the cumulative Cause Map diagram PDF for the printer:

Using the Cause Mapping® Template with an FMEA table

The FMEA and the cumulative Cause Map diagram can both be kept within our Cause Mapping Template in Microsoft Excel. The complete FMEA table with rows and columns is built on one worksheet and the cumulative Cause Map diagram is on the next worksheet in the same file.